Flow accelerated corrosion (FAC) is majorly observed in steam lines in power plants, components made up of carbon steel and low alloy steel piping, tubing and vessels those are exposed to flowing water (single-phase) or wet steam (two-phase). Susceptible areas of FAC include bends/elbows, Tees, orifices, down-stream of distributors and valves, and any location where turbulent flow exists.

Mechanisms of Flow Accelerated Corrosion:

Flow Accelerated Corrosion (FAC) refers to the combined actions involving the removal of magnetite (Fe3O4) layer by fluid flow and the subsequent increased corrosion of the exposed metal, leading to wall thinning (metal loss) to the extent of perforation.

Challenges in Inspecting FAC?

- Steam-lines operate at elevated tempers like 450°C to 500°C, thus human intervention is difficult

- Insulation removal & re-insulation post inspection will lead to considerable amount of downtime

- Flow Accelerated Corrosion is an internal wall loss phenomenon, thus removal of insulation is in vain

- Shut down is mandatory for inspection

What if we say No Shutdown required to monitor Flow Accelerated Corrosion!

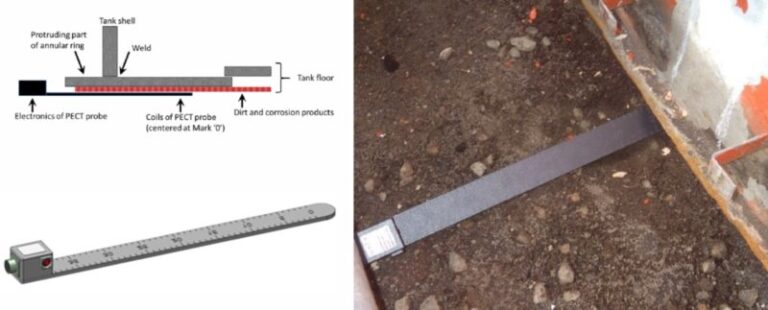

Pulsed Eddy Current (PEC) Inspection can solve the purpose without even taking a shutdown. Pulsed Eddy Current (PEC) is an electromagnetic inspection technique used to detect wall loss on ferromagnetic structures such as carbon steel and cast iron. It provides a relative volumetric measurement converted into an averaged thickness measurement based on the calibration area.

Advantages of PEC in monitoring Flow Accelerated Corrosion:

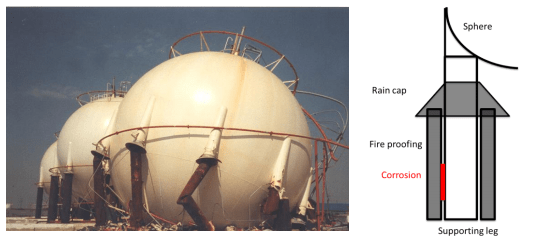

- Insulation removal not required. PEC can be performed through cladding, fireproofing, coating over test materials, thus eliminating the asset’s downtime

- PECT can be applied at high temperatures up to 550°C of metal under insulation

- Measurement accuracy of ±10% of measured wall thickness

- Pulsed Eddy Current Testing can be performed on insulation layers up to 250mm thick

- No surface preparation required

- PEC inspection is not affected by flow of fluids within the subject equipment, thus PEC can be performed during in-service conditions

- Battery powered instrument, thus perfect for remote locations

- PEC is one of the fastest screening tool available for FAC monitoring

Key Note:

The corrosion occurs at areas where the flow is distorted, such as in elbow, reducer and T-joints. The inspection can be focused on these areas, rather than 100% coverage of steam lines.

Standards guiding PEC Inspection :

ISO 20669