The tidal zone of jetty piles are commonly protected by a ‘splash zone’ coating. When this gets damaged, severe corrosion can occur, potentially undermining the structural integrity of vital harbour installations. Conventional inspections are hampered by the thick splash zone coating and the marine growth that build up.

Pulsed Eddy Current Testing (PECT) measures remaining steel thickness without having to remove the coating, deposits and marine growth. The splash zone can be inspected by rope access techniques or from boats using jigs strapped to the pile. Divers are frequently used for inspection at greater depth.

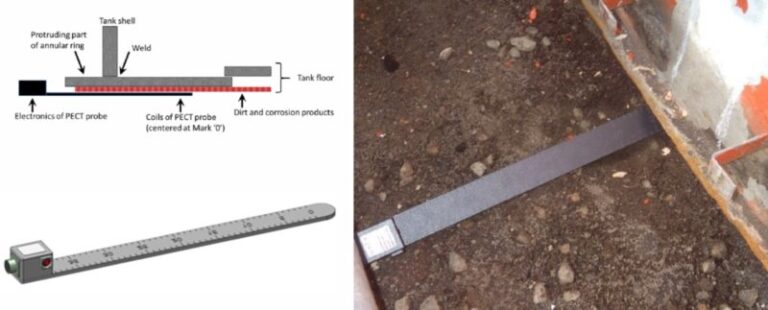

What is Pulsed Eddy Current Testing (PECT)

Pulsed Eddy Current (PEC) is an electromagnetic inspection technique used to detect wall loss on ferromagnetic structures such as carbon steel and cast iron. It provides a relative volumetric measurement converted into an averaged thickness measurement based on the calibration area.

Advantages of PECT Technology:

- It is not required to remove splash zone corrosion or marine growth, which can be as thick as 250mm

- The data is recorded in a single pulse, even for thick marine growth, enabling reliable data collection, even if waves and sea currents make it hard to keep the probe steady during data recording.

- The instrument can be connected via a 250m long underwater umbilical to a range of underwater probes.

- Measurement accuracy of ±10% of measured wall thickness.

- Battery powered instrument, thus perfect for remote locations.

- PECT is one of the fastest screening technique available for monitoring Corrosion under Splash Zone / Insulation coat in service condition.

Sample Data Presentation:

Standards guiding PEC Inspection :

ISO 20669