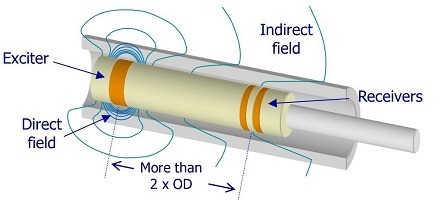

When the probe moves past a defect in the tube, the response is seen in terms of two effects:

Receiver effect

- The first receiver produces a signal when it moves past the defect, and it is followed shortly after by a similar signal from the second receiver coil.

- The subtraction of both receiver signals generates the “S” shaped differential signal.

Exciter effect

- The exciter coil moves past the defect, affecting the field sensed by the receivers.

- Both receiver coils sense the exciter effect at the same time and produce almost identical signals.

- If the defect is large, the exciter can have a small effect on the differential signal because both receiver coils have a slightly different response.